Новое поступление

XHC 6 axis Wireless MPG with Emergency Button machine hand wheel industrial lathe handwheel hot sale | Handwheel

slope jaws K13-112 six chuck self-centering lathe | Chuck

Чанчун выпускает оригинальный новый держатель инструмента с энкодером Янтай АК типа JXG-Y-P 8 12 станций на станке Шэньян ЧПУ 24V.

21517.02

SMC5-5-N-N CNC 5-осевой автономный контроллер 500KHZ Motion 7-дюймовый экран Замена Mach3 USB для гравировально-фрезерного станка.

[Original authentic] Autonics Rotary Encoder E50S8-3600-3-N-24 | CNC Controller

10208.08

MV.036.387 00.785.0353 Compatible CP Tronic Display with DNK4 Module for CD/SM102 PM/SM74 MO/SM52 | CNC Controller

64651.15

ER20 диаметр 80мм 220В 24000 об/мин 2.2КВт водяное охлаждение шпинделя + 2.2КВт инвертор + насос для воды + водопроводная труба + поддержка шпинделя + ER20 зажимы на.

33526.52

Характеристики

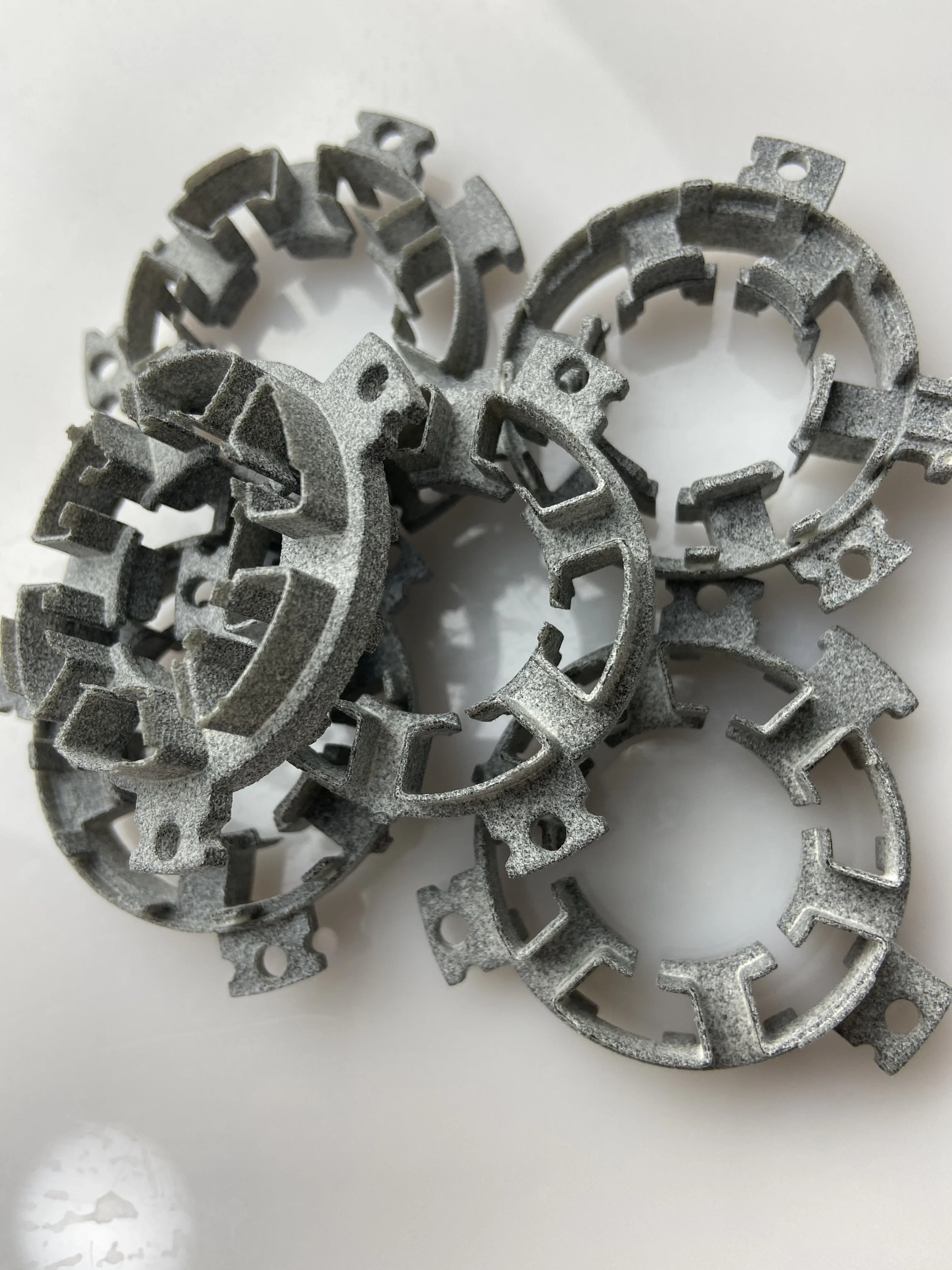

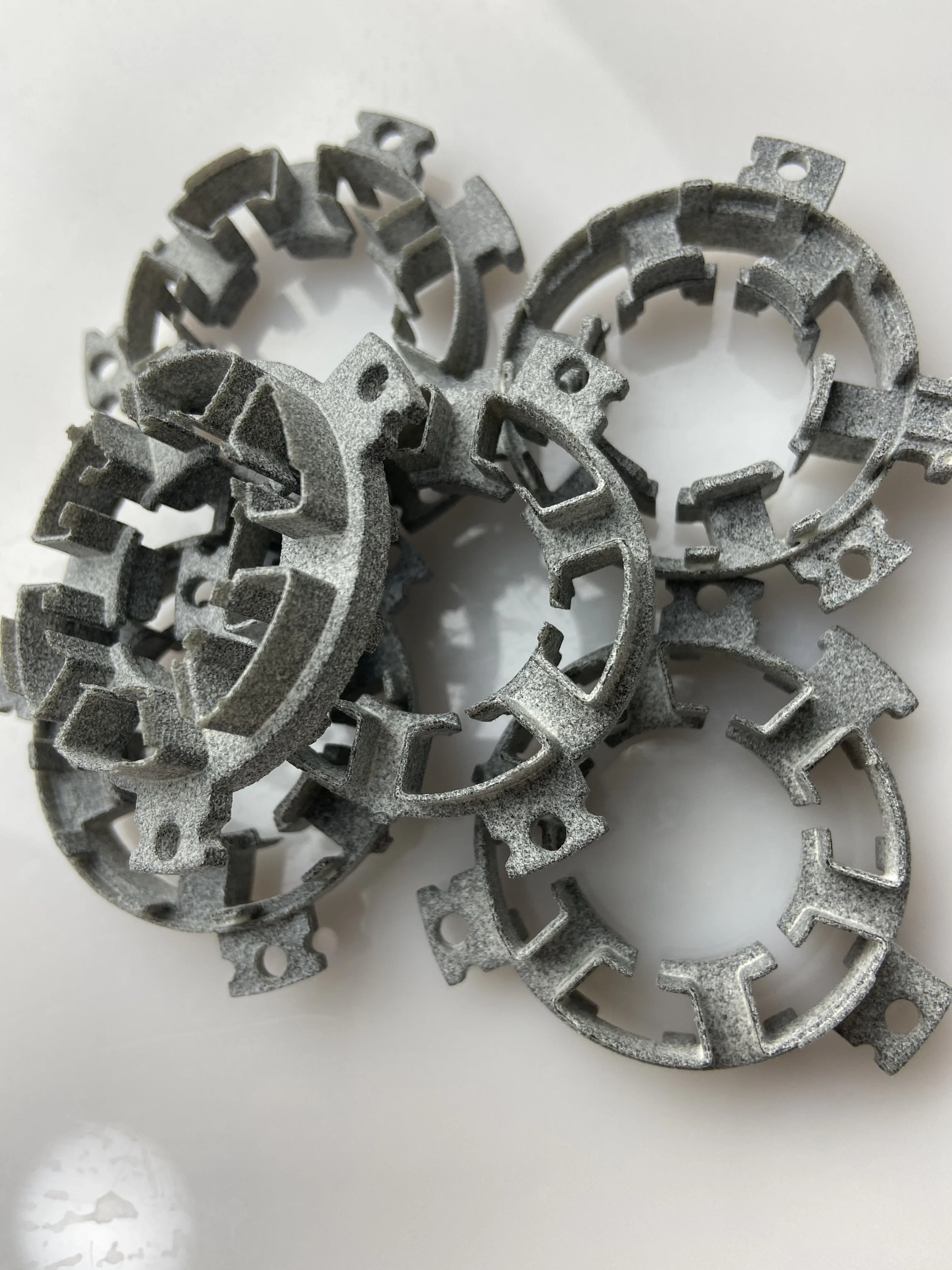

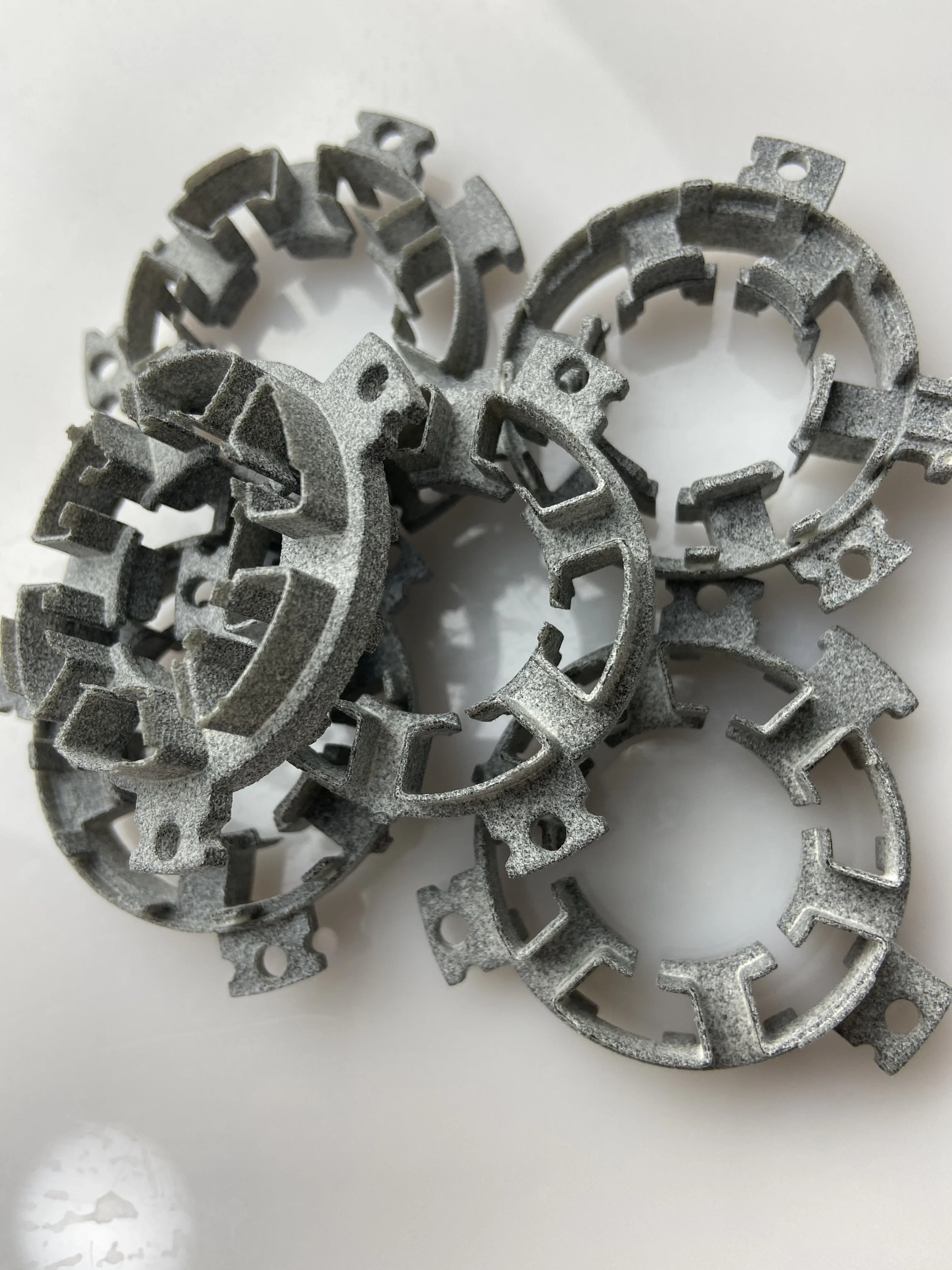

Горячая продажа на заказ пластиковых деталей из ABS и нейлона SLA SLS 3D-печать Сервис Китайская фабрика Быстрый прототип HP PA12 PA11 PA6/6 PA PA66.

История изменения цены

*Текущая стоимость 1000.79 уже могла изменится. Что бы узнать актуальную цену и проверить наличие товара, нажмите "Добавить в корзину"

| Месяц | Минимальная цена | Макс. стоимость | Цена |

|---|---|---|---|

| Sep-15-2025 | 1190.21 руб. | 1250.85 руб. | 1220 руб. |

| Aug-15-2025 | 1180.41 руб. | 1239.27 руб. | 1209.5 руб. |

| Jul-15-2025 | 990.54 руб. | 1040.1 руб. | 1015 руб. |

| Jun-15-2025 | 1160.82 руб. | 1218.85 руб. | 1189 руб. |

| May-15-2025 | 1010.7 руб. | 1061.32 руб. | 1035.5 руб. |

| Apr-15-2025 | 1140.96 руб. | 1197.42 руб. | 1168.5 руб. |

| Mar-15-2025 | 1130.21 руб. | 1187.18 руб. | 1158.5 руб. |

| Feb-15-2025 | 1120.49 руб. | 1176.81 руб. | 1148 руб. |

| Jan-15-2025 | 1110.17 руб. | 1166.9 руб. | 1138 руб. |

Описание товара

Brand NameNoneModel Number174OriginMainland ChinaCertificationRoHSMeasurement unitpiece/piecesEach pack11 000,79 ₽1 000,79 ₽loader

Description

Dear Consumers

All the product pictures on our website just showing our machining capability and ranges we offer machining service according to customer's drawings or samples

Please do not pay before we quote you .The picture and prices shown are just for exhibition, please advise us of your requirements, before we can submit a quotation

Product details

Business type | Manufacturer |

Main Product | Rapid tooling cheap manufacturing professional precision aluminium alloy custom CNC machining vacuum casting rubber SLS SLM SLA 3D printing service |

We Promise | All customer-centric, never for short-term profit, and sell long-term benefits |

CNC milling is a conventional process of rapid prototyping. It allows us to produce almost any types of 2D or 3D parts fast and cost-effectively without using mass-manufacturing methods. Our customers use this service to make parts for concept evaluation, fit/function testing, demonstration or short-run production. Examples of parts include machine parts, metal or plastic structures, mould tooling, scale models and toy parts.

Equipment

quipmentWe have precision CNC milling machines with travel distance from 450mm, 850mm up to 1,200mm, which means the longest single part we can handle is 3,000mm*600mm . Though longer structures can be divided into several shorter parts to be machined and once the job is done the parts can be assembled. We also have access to high-end 4-axis CNC machines ,so as to cater our customers’ complex demand.

Tolerance

Plastic and metal: regular tolerance 100mm ± 0.1mm. Assembly is guaranteed.

Metal: minimal tolerance 100mm ± 0.02 if required. Assembly is guaranteed.

Materials

We can handle most hard materials in the CNC milling process.

Metals: 6xxx series and 7xxx series aluminium (e.g. 6061 aluminium or 6063 and 7075 aviation grade aluminium), brass, 45# steel and stainless steel etc.

Plastic :ABS,PP,PMMA,PA ,PC,POM ,PTFE,PE,PEI ,PEEK ,PPS etc.

Surface Treatment

• Sanding • Polishing • Sand blasting • Primer painting • Spray painting • Electroplating

• Anodizing

• Silk-screening (artwork file required. .AI format preferred)

From one single finished part (master), vacuum casting can produce multiple high quality and faithful replicas of the master. This method is low-cost and fast for short-run production. Customers can choose from a wide range of plastics and polymers, e.g. ABS, Polyurethane, clear acrylic and soft rubber, to achieve desired mechanical properties and surface finish. Available shore hardness from 45A to 90A.

SLA can be used in rapid prototyping and model testing as it has such advantages as high quality surface and precise dimensions. Due to its easy handling and high-standard quality, this equipment is widely used in prototyping. Application can be mobile phone, aircraft model and high precise machinery and home appliance and so on.

Materials

Somos 11122(Water clear,ABS)

Somos EvoLVe 128 (Flexible)

Somos Imagine 8000 (harder)

High temperature Grey ABS like ,Support 80℃

High temperature Black ABS like ,Support 73℃

etc.

Components made by SLS technique have got a broad prospect in fields of automobile, electric tools, electric appliance and aviation industry with its advantages including efficiency and excellent mechanical performance, low rate of water absorb, anti-aging and anti-chemical erode,. Besides, the production speed of SLS is faster than the general process. It is suitable to do mold testing, functional model and production of small batch parts. Above all, it’s the best technology for direct parts at current stage.

Materials

eos : PA 2200

eos : PA+GF 3200

Apart from providing production design and rapid prototyping, and established a high profile and up-scale injection molding center in this area. These years, we have successfully entered markets in developed countries like EU and USA. Our clients fully trust our good quality and on time delivery.

In order to provide clients more completed and outstanding one-stop service, established injection molding all these conditions can meet the US FDA and ROHS, requirements based on our rich experience in injection molding. Our specialty lies in high precision and our tolerance

for the parts can guarantee to be 0.05mm/100mm.

Please send your 3D files and the description of parts/jobs to our email address.:

we accept .STP or .STEP,IGS,STL etc. file format.

Once we receive the complete file, we will confirm with you immediately and provide a quotation in USD ($) within 12 hours. For some complicated files and jobs, it may take up to 24 hours for us to offer a quotation.

The parts are produced in China and will be shipped from China. We can ship your parts by couriers (EMS, SF, FedEx, UPS, DHL and TNT,) or by air freight world-wide. You may also specify a shipping method.

Standard payment terms: pay 50% deposit in advance, 50% balance before shipment online trade assurance order, all is up to you

More payment terms could be provided (TT )

Please do not hesitate to contact me when you need any service.

Looking forward to hear your news soon

Смотрите так же другие товары:

![[Original authentic] Autonics Rotary Encoder E50S8-3600-3-N-24 | CNC Controller](http://ae04.alicdn.com/kf/HTB1WtppR3HqK1RjSZFkq6x.WFXa7.jpg)