Новое поступление

Stainless Steel Spokes J-hook spokes or straight pull Pillar PSR Aero 1432 spoke | Спорт и развлечения

Горный велосипед электронный спицевой измеритель напряжения надежный точный

Спицы мотоцикла 8K 4 0 ММ 36 шт. в партии спицы 304 из нержавеющей стали J-bend

8 # 4.0 mm Straight Head Motocross Spokes Material 304 Stainless Steel Cylinder Motorcycle Wheel With SUS Nipples | Спорт и

12 шт. в упаковке езда на велосипеде для велосипеда спиц отражатель

36 шт./компл. цветная велосипедная мотоциклетная горная велосипеда модификация

36 шт. велосипедные спицы проволока для горного/дорожного велосипеда 2 0 круглые

Характеристики

Bicycle Tool Spoke Tension Meter For MTB Road Bike Wheel Spokes Checker Reliable Indicator Accurate Stable Repair | Спорт и

История изменения цены

*Текущая стоимость 369,97 - 1 236,26 уже могла изменится. Что бы узнать актуальную цену и проверить наличие товара, нажмите "Добавить в корзину"

| Месяц | Минимальная цена | Макс. стоимость | Цена |

|---|---|---|---|

| Aug-15-2025 | 469.89 руб. | 478.37 руб. | 473.5 руб. |

| Jul-15-2025 | 380.33 руб. | 388.49 руб. | 384 руб. |

| Jun-15-2025 | 461.51 руб. | 470.53 руб. | 465.5 руб. |

| May-15-2025 | 458.60 руб. | 467.88 руб. | 462.5 руб. |

| Apr-15-2025 | 365.82 руб. | 372.44 руб. | 368.5 руб. |

| Mar-15-2025 | 450.50 руб. | 459.77 руб. | 454.5 руб. |

| Feb-15-2025 | 446.3 руб. | 455.87 руб. | 450.5 руб. |

| Jan-15-2025 | 443.99 руб. | 452.50 руб. | 447.5 руб. |

Описание товара

Bike Indicator Attrezi Meter Tensiometer Bicycle Spoke Tension Wheel Builders Tool Bicycle Spoke Repair Tool

Brand: MEROCA,

Name: Spoke Tension Meter

Material: aluminum alloy

Size: 167*115mm

Weight: 146g/piece

Color: black/red

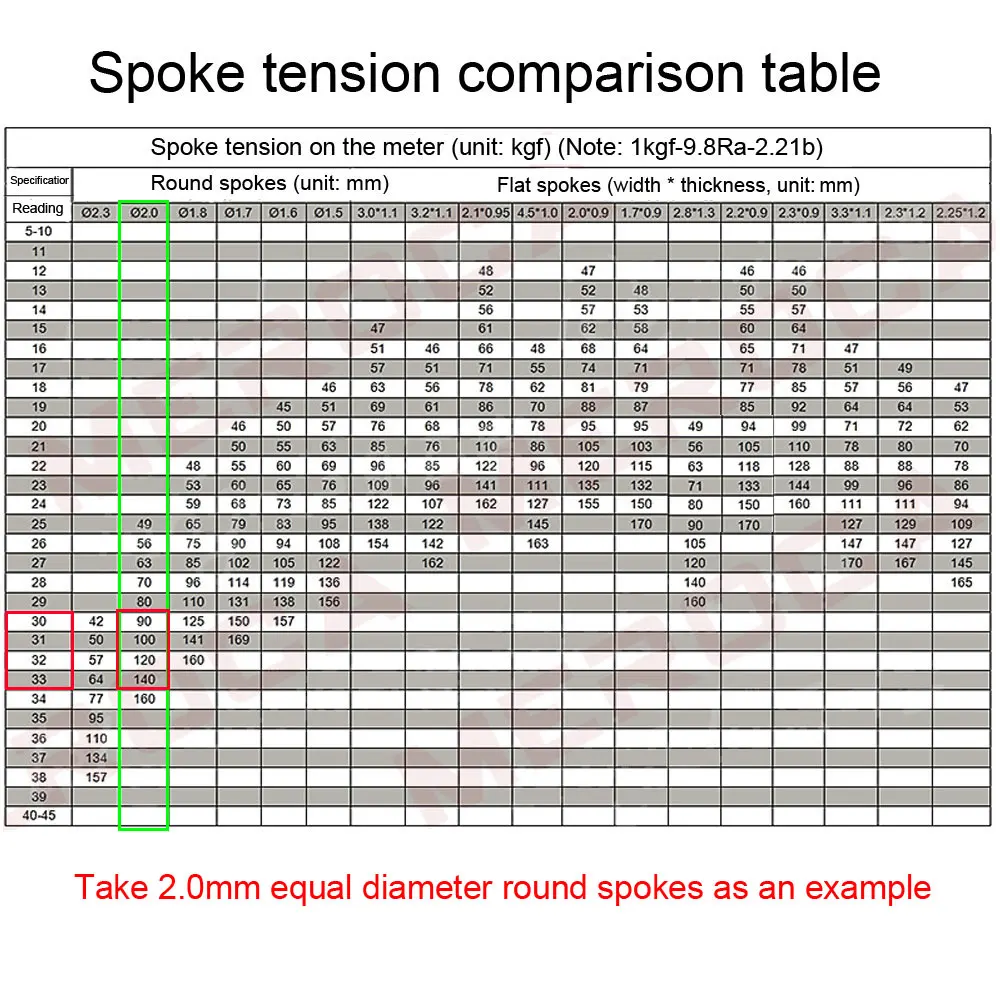

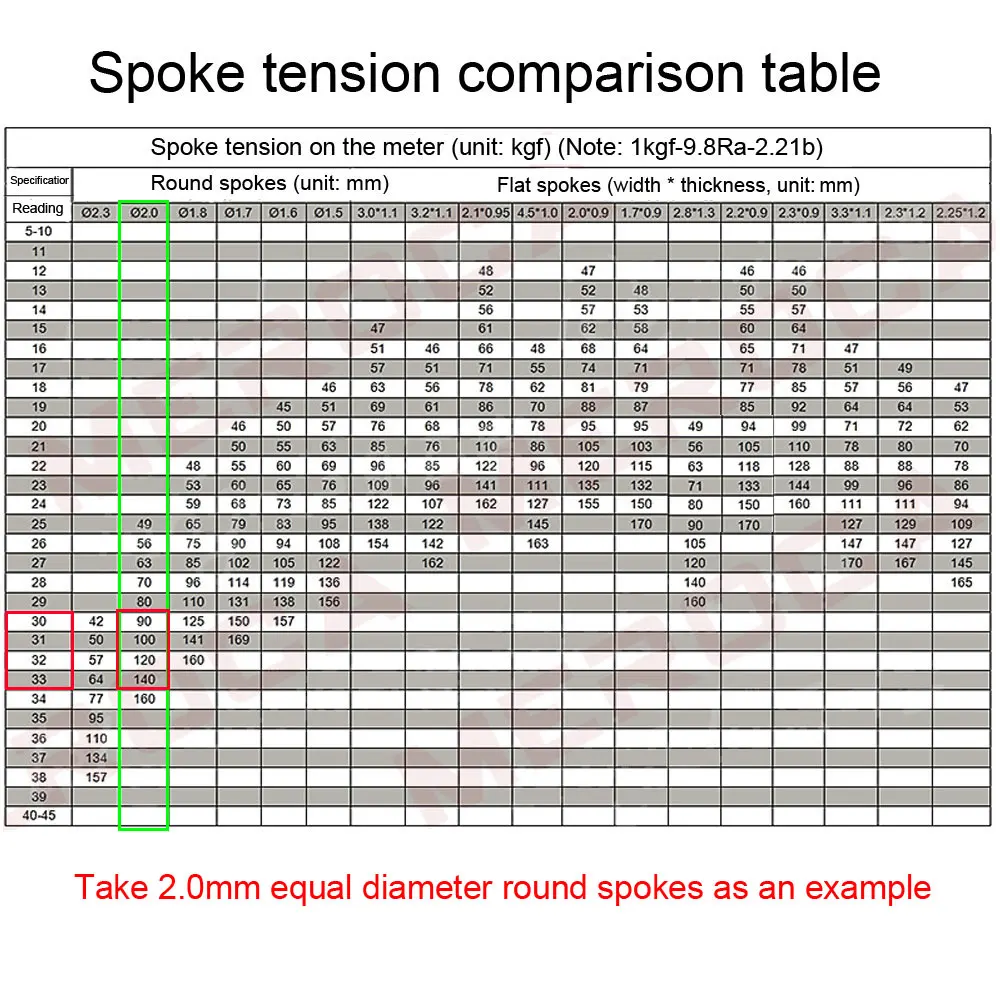

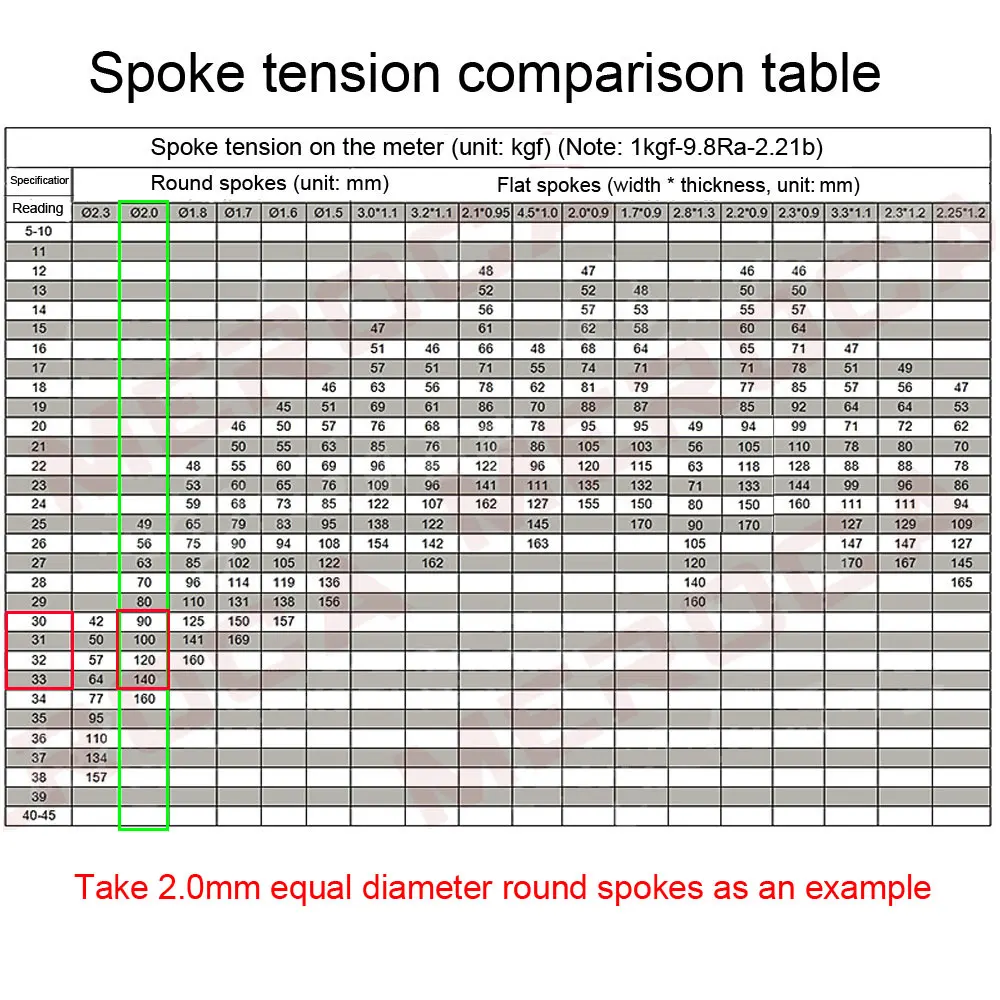

Reading: refer to the spoke tensiometer comparison table

Purpose: To measure the tension of spokes, suitable for round spokes, flat spokes and spoke tensions of various wheel sets.

What is a Spoke tensiometer ?

Spoke tension is the amount of pulling force being exerted along a spoke. It is typically measured and called out by component companies in Kilograms of force (kgf), or in Newtons (N).

Why I need a Spoke tensiometer ?

When truing or dishing a wheel, the mechanic is making adjustments that affect spoke tension. However, spoke tension isn’t just about individual spokes. Rather, good tension looks at the entire wheel system with the goal being consistently good tension between all the spokes.

When a bike is being ridden, the wheel flattens slightly where it meets the ground. As this happens, the tension of the spokes at the bottom of the rim drops. This cycle of gaining and losing tension happens throughout the entirety of each ride. If a wheel’s tension is too low, it can cause the spokes to relax too much during a ride, creating a snapping effect and causing excess stress to both the spokes and the rim. This can lead to de-tensioning, which is when spokes lose tension over a short amount of time. This can lead to broken spokes, rim fatigue and a wheel that will go out of true more often. At the other extreme, too high of tension can lead to wheel failures like cracked rims, broken spokes or even damaged hubs. A properly-tensioned wheel is stronger, and stays true longer.

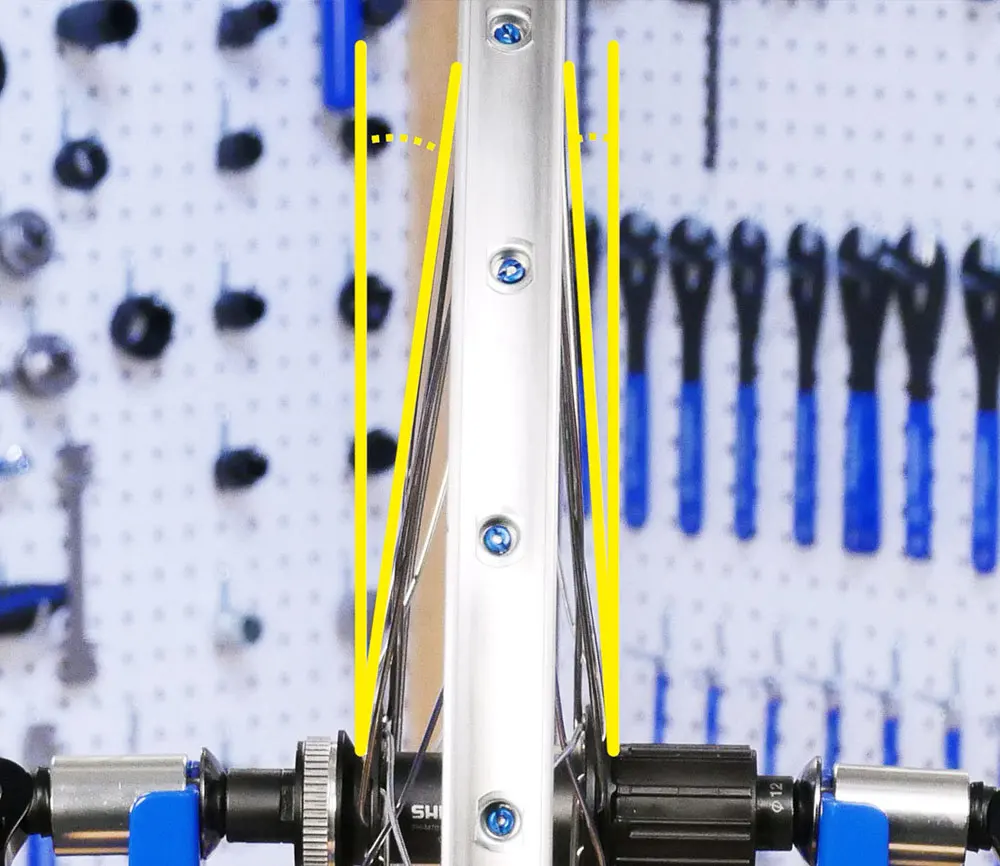

Tension measurement

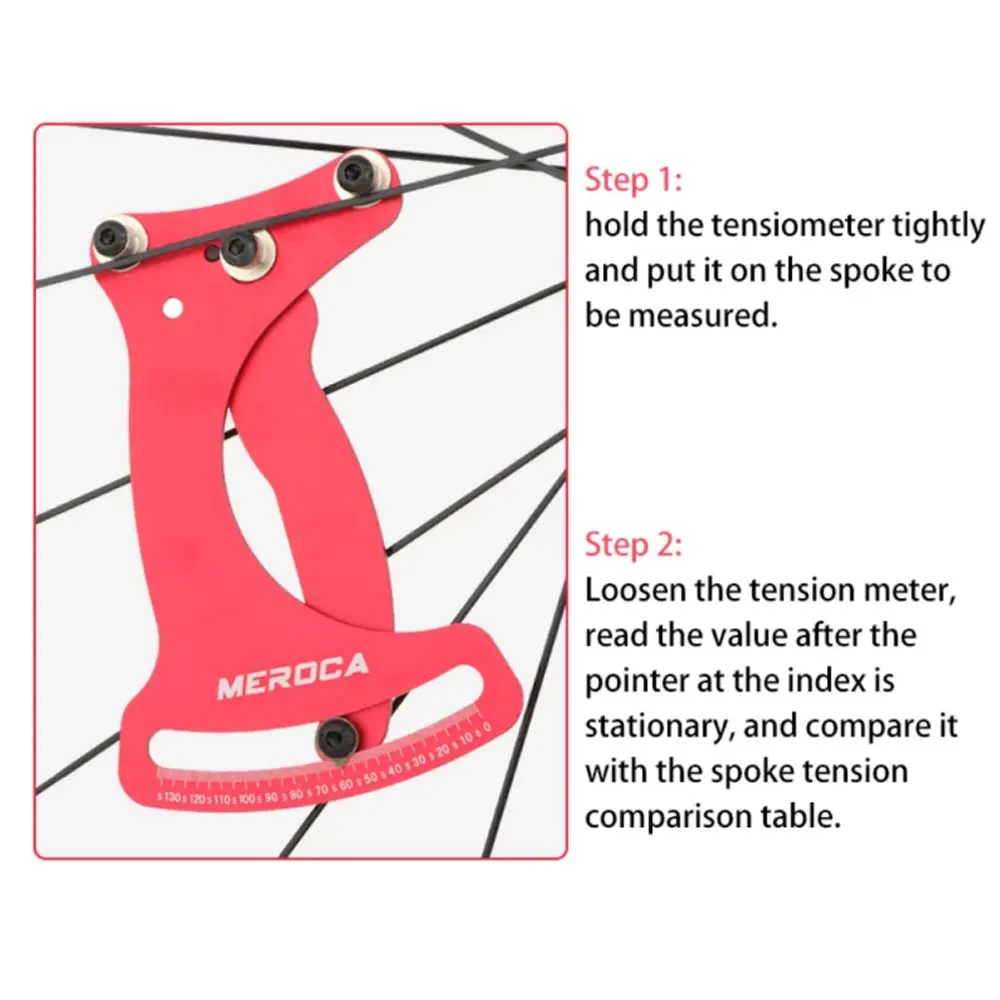

The most accurate and precise way to measure spoke tension is with a spoke tensiometer like the MEROCA TN-1. Spoke tensiometers flex a spoke between two posts with a calibrated spring. This deflection is shown on the meter’s scale.

1.Determine the material of the spoke. Steel spokes will have a magnetic pull - test with a magnet.

2.Determine the diameter (for round spokes) or dimensions (for bladed spokes) of the spoke. Measure in the middle of the spoke using a caliper or the spoke diameter gauge included with the TN-1.

3.Squeeze the TN-1 at the handle grips. Place the spoke between the two fixed posts and the moveable post of the TN-1. With aero/bladed spokes, position the posts so they rest against the wide, flat side of the spoke. Gently release handles.

4.Note the reading on the scale of the TN-1.

On rear wheels and wheels with disc brakes, notice that the readings are lower overall on one side. This is due to the fact that the spokes come out of the hub at different bracing angles. This is the angle at which a spoke leaves the hub and travels to the rim. When the spoke has a larger angle, it has more mechanical advantage and will require less tension to counter the opposing side. Your tension goal applies to the side with more tension. The opposing side will simply have lower tension when the centering, or dish, is correct.Most rear wheels have offset hub flanges to accommodate the rear sprockets.

Tension adjustment

To adjust spoke tension it is helpful to have something to hold the wheel as you work, like a MEROCA truing stand or wheel holder. You’ll also need a properly sized spoke wrench to turn the spoke nipple - see Spoke Wrench Selection for more information.

Tension balancing and relative spoke tension.

You may have noticed that as you take readings that there is some fluctuation between spokes on the same side.

If these vary widely, the wheel can benefit from tension balancing, where you tighten and loosen individual spokes to even out the tension of the wheel. A wheel with spokes that are within plus or minus 20% of the wheel’s average spoke tension is generally considered to have acceptable relative tension.

TN-1 Calibration

It is recommended for professional mechanics and service departments use a non-riding wheel to help in tool calibration. Remove the axle from a wheel so that it is not rideable. Mark a spoke as a reference spoke and measure this one spoke. Write the date of the measurement directly on the rim. This same spoke can be used to double check the original calibration. If the tool is reading different than this “reference spoke,” the spring tension can be changed. If the tool is reading low, take the tool off the spoke and turn it upside down. Remove the spring from the fixed moving stud, and then thread the adjusting screw inward toward its stud. This will decrease tension on the TN-1 spring, resulting in a higher deflection reading. If the TN-1 is reading high, increase tension at the adjusting screw.

Смотрите так же другие товары: