Новое поступление

Рюкзак мужской на молнии с двумя небольшими сумками Повседневный для

Новый костюм на Хэллоуин костюмы для косплея черепа скелета демона призрака

Диабетические Лазерные Терапевтические часы для лечения гипертонии 650 нм 808

Hot Fruit Pineapple Lemon Banana Soft Silicon Transparent Case Cover For Apple iPhone 4 4S 5 5S SE 5C 6 6S 6Plus 6sPlus Coque |

Светодиодная лампочка эдисона E27 5 Вт Холодный/теплый белый свет |

Для Huawei Y7 prime 2018 чехол Nillkin матовая жесткая задняя крышка из ПК для huawei enjoy 8 с

2x100% хлопок детское клетчатое мягкое одеяло детская кроватка кровать мхи корзина

Характеристики

Dinghua rework 220v DH-390 infrared soldering station universal bga reballing kit with two upper heads and iron |

История изменения цены

*Текущая стоимость уже могла изменится. Что бы узнать актуальную цену и проверить наличие товара, нажмите "Добавить в корзину"

| Месяц | Минимальная цена | Макс. стоимость | Цена |

|---|---|---|---|

| Sep-16-2025 | 0.3 руб. | 0.0 руб. | 0 руб. |

| Aug-16-2025 | 0.86 руб. | 0.74 руб. | 0 руб. |

| Jul-16-2025 | 0.29 руб. | 0.38 руб. | 0 руб. |

| Jun-16-2025 | 0.42 руб. | 0.42 руб. | 0 руб. |

| May-16-2025 | 0.98 руб. | 0.83 руб. | 0 руб. |

| Apr-16-2025 | 0.32 руб. | 0.52 руб. | 0 руб. |

| Mar-16-2025 | 0.55 руб. | 0.77 руб. | 0 руб. |

| Feb-16-2025 | 0.84 руб. | 0.75 руб. | 0 руб. |

| Jan-16-2025 | 0.72 руб. | 0.14 руб. | 0 руб. |

Описание товара

Dear friends, thank you for your visit to our store.

We are the professional manufacturer of bga rework stations. We will help you to improve the rework rate of bga chips.

Dinghua rework 220v DH-390 infrared soldering station universal bga reballing kit with two upper heads and soldering iron

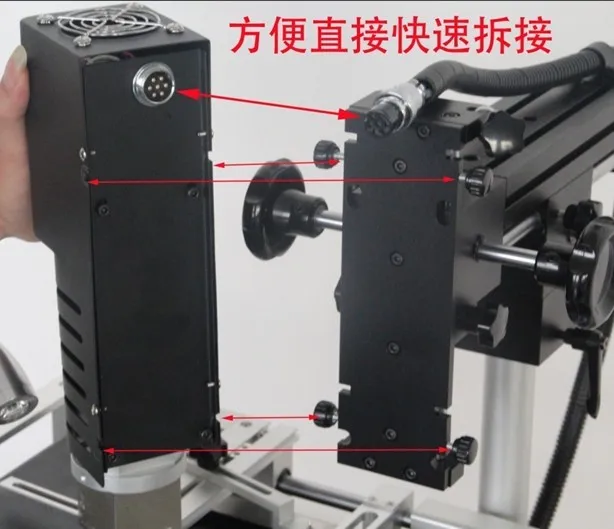

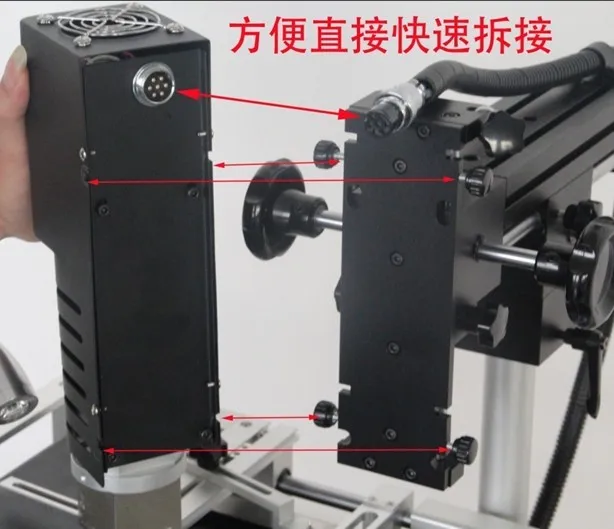

Two upper heaters, one hot air and one infrared. Easy to install and change

Add one soldering iron, convenient to bga chip reball

Main Parameters:

| Power |

4350W/4800W |

| Top heater |

450W/800W |

| Bottom heater |

Second heater 2700W, IR preheating 1200w |

| Power supply |

AC220V 50/60Hz |

| Dimensions |

560*530*590mm |

| Positioning |

V-groove, PCB support can be adjusted in any direction with external universal fixture |

| Temperature control |

K Sensor close loop control |

| Temp accuracy |

2 degrees |

| PCB size |

Min:20mm*20mm, Max:320mm*375mm |

| BGA chip |

2*2~80*80 |

| Minimum chip spacing |

0.15mm |

| External Temperature Sensor |

1 |

| Net weight |

32 kG |

Description:

1. Two top heating: hot air heating and infrared heating

2. Bottom heaters are hot air heating, the third heating is infrared heating, temperature accuracy within 2 degrees, the top and bottom heaters can set 8 segments rising temperature and 8 segments activity temperature.

1. PLC control, and instant profile analysis function. Real-time settings and actual temperature profile display can be used to analyzed and correct parameters if necessary.

2.It uses precise K-type close circuit control and automatic temperature adjustment system, with PLC and temperature module to enable precision temperature control of 2 degC. External temperature sensor enables temperature monitoring and accurate analysis of real time temperature profile.

3.V-groove PCB support for rapid, convenience and accurate positioning that fits for all kinds of PCB board.

4.Flexible and convenient removable fixture on the PCB board which protectsand prevent damage to PCB. It can also adapt to rework various BGA packages.

5.Various sizes of BGA tianium nozzles, which can be adjusted 360 degree for easy installation and replacement;

6.There are 6 to 8 levels of variable and constant temperature controls. 10 groups temperature curves which are Instant accessible according to different BGA. Curve analysis, setting and adjustment are all accessible via touch screen. Three heating areas adopts independent PID calculation to control heating process to enable more accurate and precise temperature control.

7.It uses high power fan to enable fast cooling of PCB board and prevent it from deformation. There are also internal vacuum pump and external vacuum pen to assist with fetching the BGA chip.

8.Equipped with constant temperature digital display soldering iron.

9.Including Voice "early warning" function. 5-10 seconds before the completion of uninstalling or welding, voice reminder / warning to get the workers prepared. Cooling system will start after vertical wind stopped heating. When the temperature drops to room temperature, the cooling process will stop, so that the machine will not age after heated up.

10.CE certification, with emergency switch and automatic power-off protection device when emergency happens.

Warranty:

1. One year for the whole machine and three years for the heaters. (2 years longer than other suppliers)

2. During warranty time, we will offer the spare part for free, but customer will charge the shipping cost. We will also teach you how to stall it.

Shipment:

1. Normally we will offer 3 days' free test before the machine out of factory.

2. Machine is packed in wooden case.

3. We can ship through DHL or Fedex. If you need other shippment pls contact us.

Смотрите так же другие товары: