Новое поступление

1 шт. GT2 шкив 16/20 зубчатый диаметр 5 мм 6 35 8 Зубчатый редуктор из алюминия для 2GT

10 шт. устойчивые к растворению щетки стеклоочистителя для печатающих головок Dx5

Пылезащитный чехол для 3D принтера светозащитный и звукостойкий защитный Elegoo Saturn

100 метров открытой ремень 3D-принтер Запчасти GT2 зубчатый резиновый 2gt 6 мм

1 шт. 6*35 5*9 мм U Рифленое колесо 626zz обернутое пластиковым нейлоном инженерное

1 pcs Aluminum Alloy plate Heat Sink M6 Thread Cooling Pipe Radiator whools Diameter 30mm for E3D V6 3D Printer parts | Компьютеры и

5pcs VK-162 VK162 VKEL GPS V.KEL engine board /Module with Antenna USB G-Mouse Support for Google Earth Manufacturer DIRECT SALE |

OPEN SOURCE Series Store

Магазина OPEN SOURCE Series Store работает с 12.05.2014. его рейтинг составлет 94.23 баллов из 100. В избранное добавили 402 покупателя. Средний рейтинг торваров продавца 4.8 в продаже представленно 521 наименований товаров, успешно доставлено 379 заказов. 208 покупателей оставили отзывы о продавце.

Характеристики

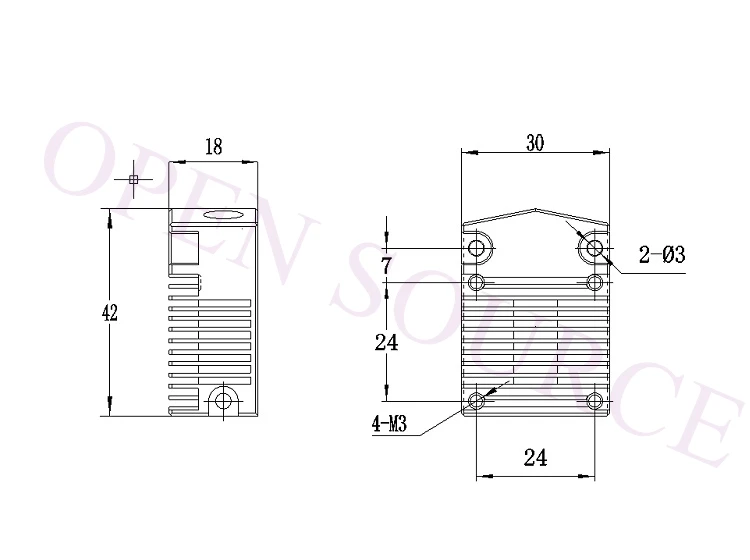

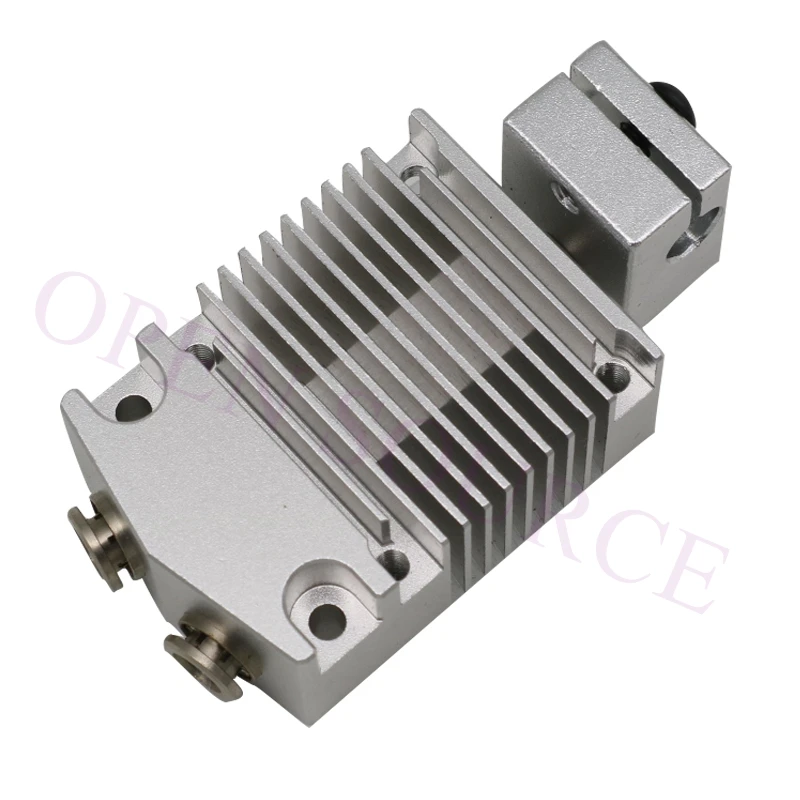

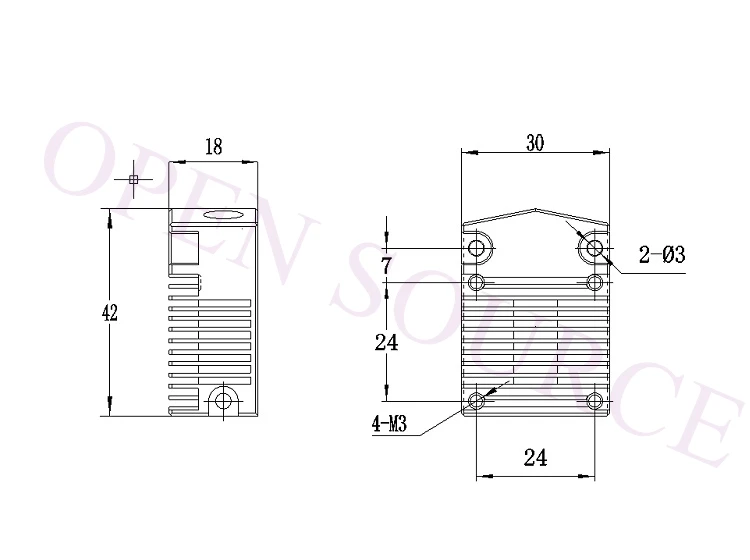

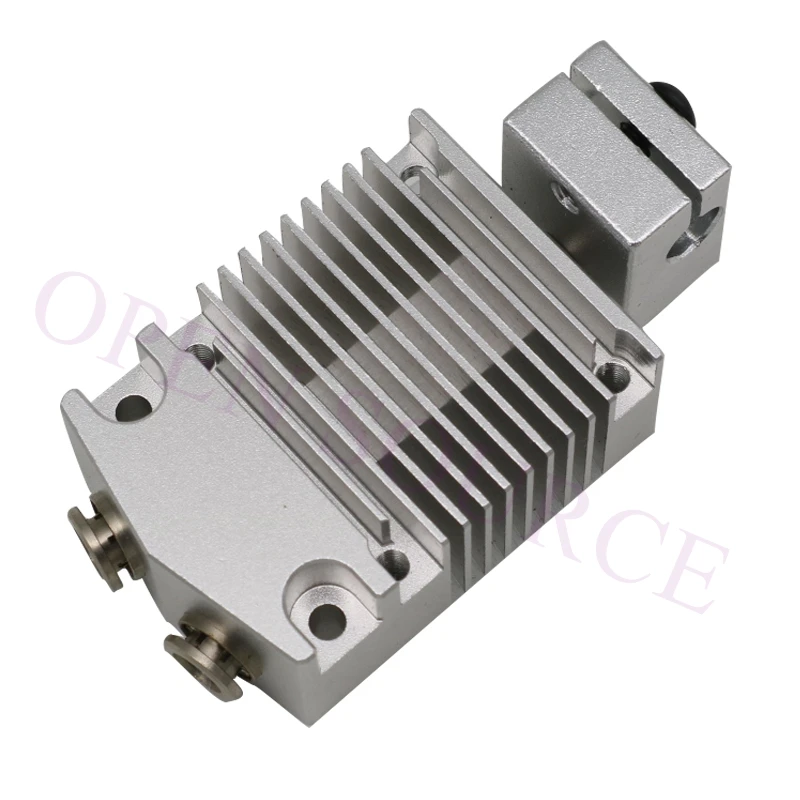

New Desgin Cyclops Extruder 2 In 1 Out colors Hotend Bowden Compatible with Titan Bulldog extruder | Компьютеры и офис

История изменения цены

*Текущая стоимость US $23.46 уже могла изменится. Что бы узнать актуальную цену и проверить наличие товара, нажмите "Добавить в корзину"

| Месяц | Минимальная цена | Макс. стоимость | Цена |

|---|---|---|---|

| Aug-16-2025 | 29.26 руб. | 30.29 руб. | 29.5 руб. |

| Jul-16-2025 | 24.88 руб. | 24.6 руб. | 24 руб. |

| Jun-16-2025 | 29.38 руб. | 30.43 руб. | 29.5 руб. |

| May-16-2025 | 29.38 руб. | 30.51 руб. | 29.5 руб. |

| Apr-16-2025 | 23.27 руб. | 23.98 руб. | 23 руб. |

| Mar-16-2025 | 28.6 руб. | 29.37 руб. | 28.5 руб. |

| Feb-16-2025 | 28.37 руб. | 29.37 руб. | 28.5 руб. |

| Jan-16-2025 | 28.21 руб. | 29.99 руб. | 28.5 руб. |

Описание товара

Смотрите так же другие товары: