Новое поступление

3-шт. сверла с шестигранным хвостовиком дюймовых размеров из высокоскоростной стали 4241 для сверления отверстий в латуне, дереве и пластике с ручкой на шестиугольной лестнице.

Extra Long Wood Hole Saw Auger Drill Bit 20x460mm |

Самоцентрирующаяся сверлильная петля 5 мм/1/4" для дверей, окон и кабинетов с наконечником для сверления отверстий в дереве и пластике из высокоскоростной стали (HSS) с пильным диском для столярных работ.

Набор сверл Diamond Drill Bit Set 11PCS Hollow Core Hole Saw с направляющим приспособлением подходит для керамических плиток.

Профессиональный автоматический центральный отверстие Pin Punch Spring Loaded Screw Auto Marking Drilling Tool HHS Tip Brass Body Gold Color.

Набор сверл с центровщиком 3 шт. 12-16-19 мм для дерева и металла с быстросменным хвостовиком из углеродистой стали.

Набор адаптеров для сверл комплект твист-ступенчатых направляющих коронок 9 мм с

XJ NC tool shop

Магазина XJ NC tool shop работает с 12.03.2015. его рейтинг составлет 96.84 баллов из 100. В избранное добавили 3019 покупателя. Средний рейтинг торваров продавца 4.9 в продаже представленно 2446 наименований товаров, успешно доставлено 20555 заказов. 8255 покупателей оставили отзывы о продавце.

Характеристики

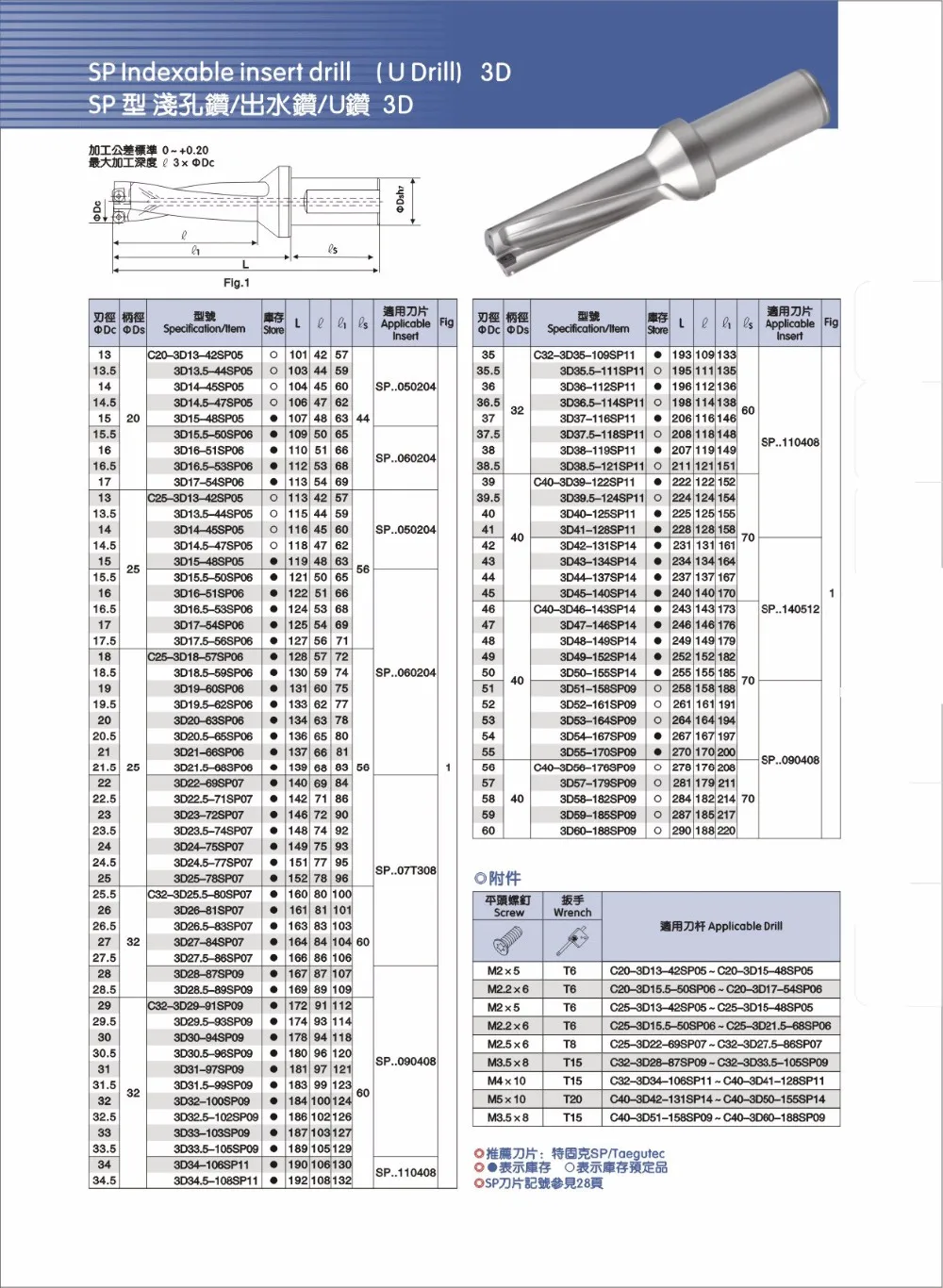

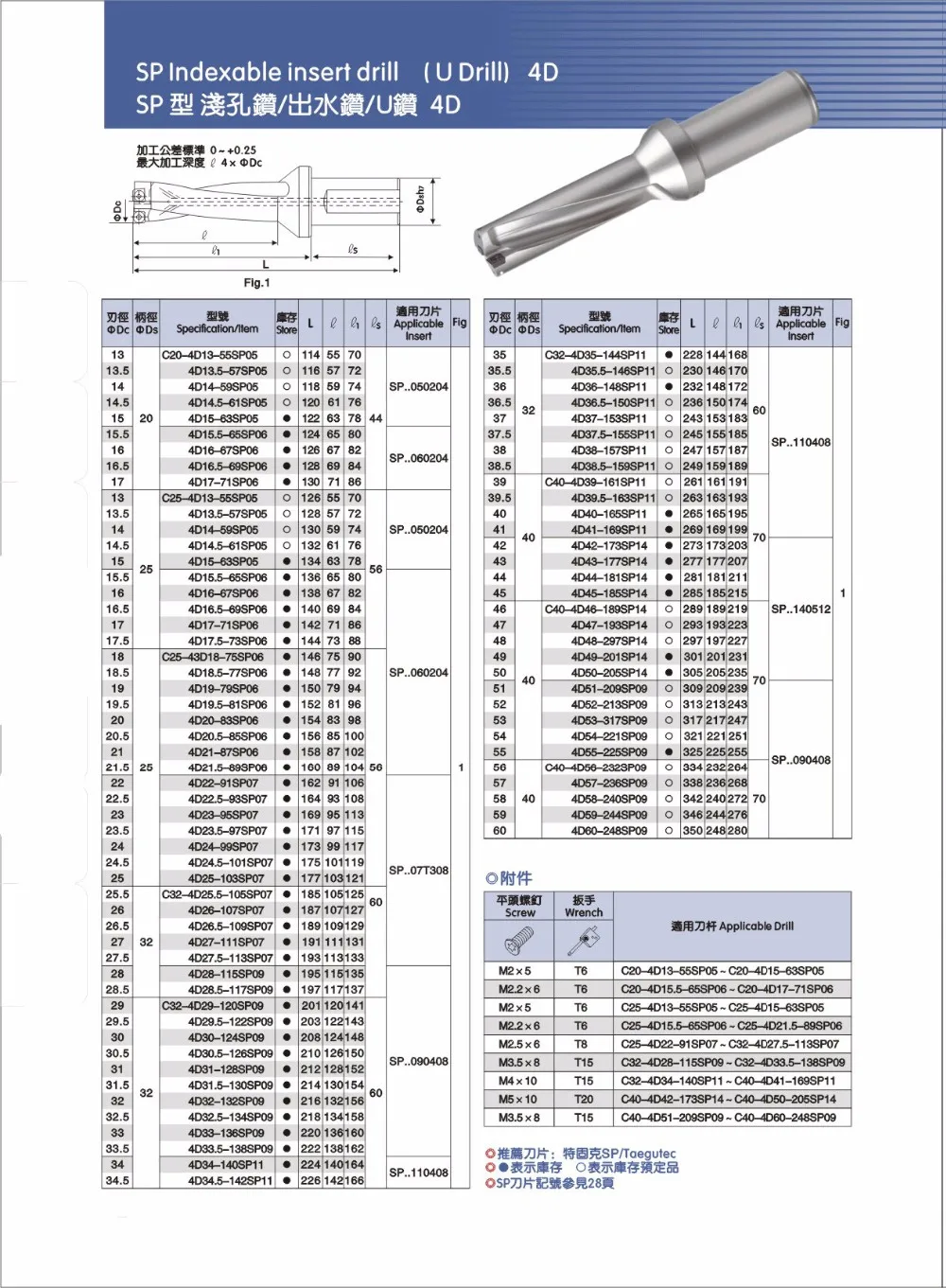

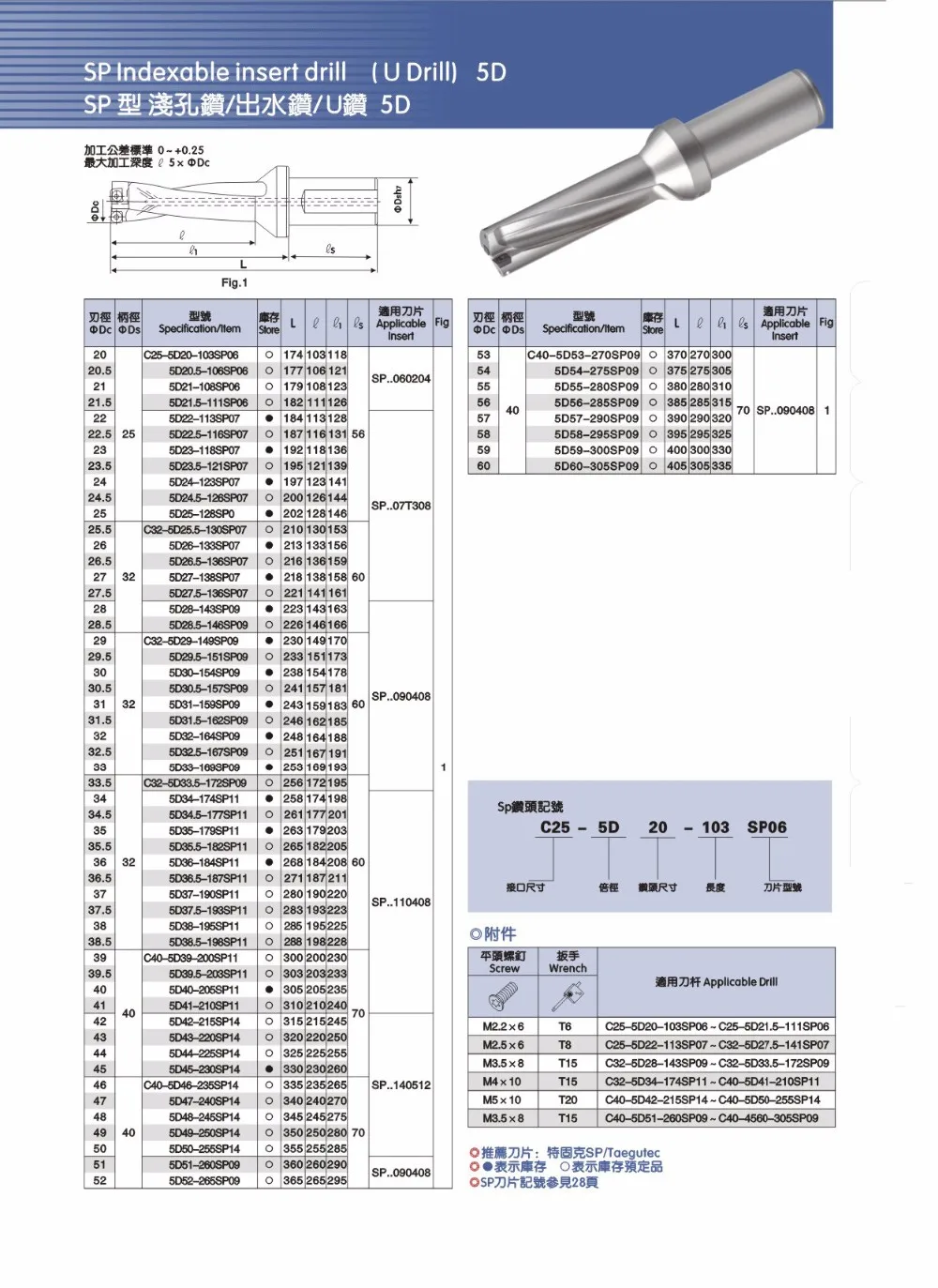

SP C25/C32-2D-SD20.5--SD25 заменить лезвия и сверла типа для вставок SPMW SPMT U сверление мелких отверстий на пластинах сменных режущих пластин.

История изменения цены

*Текущая стоимость 3177.68 уже могла изменится. Что бы узнать актуальную цену и проверить наличие товара, нажмите "Добавить в корзину"

| Месяц | Минимальная цена | Макс. стоимость | Цена |

|---|---|---|---|

| Aug-15-2025 | 4035.55 руб. | 4116.67 руб. | 4075.5 руб. |

| Jul-15-2025 | 3272.17 руб. | 3337.40 руб. | 3304.5 руб. |

| Jun-15-2025 | 3971.50 руб. | 4050.72 руб. | 4010.5 руб. |

| May-15-2025 | 3939.45 руб. | 4018.4 руб. | 3978.5 руб. |

| Apr-15-2025 | 3145.47 руб. | 3208.67 руб. | 3176.5 руб. |

| Mar-15-2025 | 3876.48 руб. | 3954.85 руб. | 3915 руб. |

| Feb-15-2025 | 3844.81 руб. | 3921.98 руб. | 3882.5 руб. |

| Jan-15-2025 | 3812.8 руб. | 3888.71 руб. | 3850 руб. |

Описание товара

Description

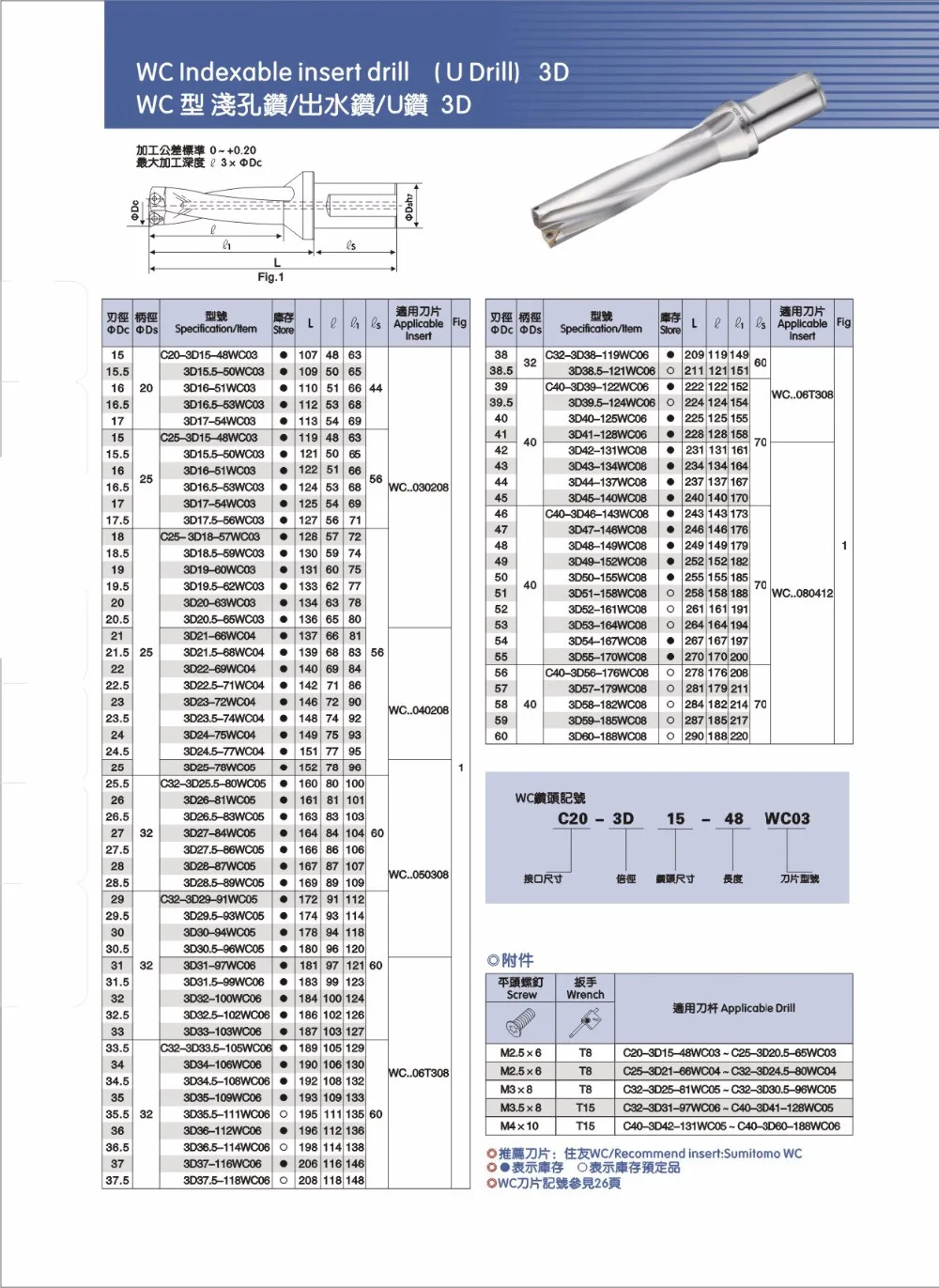

Specific models are as follows:

SP C25-2D-SD20.5-SP06

SP C25-2D-SD21-SP06

SP C25-2D-SD21.5-SP06

SP C25-2D-SD22-SP07

SP C25-2D-SD22.5-SP07

SP C25-2D-SD23-SP07

SP C25-2D-SD23.5-SP07

SP C25-2D-SD24-SP07

SP C25-2D-SD24.5-SP07

SP C32-2D-SD25-SP07

Fast drilling with Blade Type: SD14-SD20: WCMT030208FN ACZ330 screw: M2.5 * 6.5 wrench: T8 SD21-SD24: WCMT040208FN ACZ330 screw: M2.5 * 6.5 wrench: T8 SD25-SD30: WCMT050308FN ACZ330 screw: M3 * 7 Wrench: T8 SD31-SD41: WCMT06T308FN ACZ330 screw: M3.5 * 8 Wrench: T15 SD42-SD60: WCMT080412FN ACZ330 screw: M4 * 10 Wrench: T15 Since u drill customer purchases, will be more questions, we first do some basic instructions (A) solid edge special U drill are their own factories timber train operations, quenching, manufacturing, testing. (2) the quality can be assured, which can replace Taegutec other high-end brands. (3) Our prices are very reasonable, and please do not compare the market cheap U drill. (4) Type Description (case C25-SD20.5-25-4D) Representative shank diameter C25 SD20.5-25D representative 20.5 / 21 / 21.5 / 22 / 22.5 / 23 / 23.5 /24/24.5 is the same price 4D representative U drill length (handle length is not) 4D = 4 times the diameter, U is the length of the drill diameter X4 (5) U drill will be white and black two models, quality and price are the same, then shipped. We are the default general photographed baby hair with triangular blades WCMT type, If the need is flat bottom hole drilling requires Remarks about, we will send with SPMG type blade. Buyer Note: U drill holes for roughing tool diameter is generally played are considered normal range of plus or minus 0.2 When used, as high pressure center of the water, can increase blade life and chip evacuation When applicable CNC lathes, props to the center and the center of the mechanical axis parallel Drill drill: Drill drill drill is an important factor for success. Ensure good quality of the method is to ensure that the hole drilled into the surface of the drill perpendicular to a central axis of the workpiece. In addition, indexable drill shallow holes can also adjust the feed to the processing convex, sloping and irregular concave surface drill. General notes: strongly recommended to use the high-pressure center cutting cold way, the cold cutting can maximize the effectiveness of the drill cutting, effectively prevent the accumulation of chips, blades damaged and destroyed a machine machined inner surface to ensure the reliability of the processing using external cooling mode drilling, drilling depth should not exceed 1.5D; drilling depth when necessary, recommended pecking way process For best drilling results are as follows: detect steel shank minimize the deviation between the tool and the spindle axis use the recommended cutting mode drilling depth 2D / 3D when coolant minimum 4KG / cm⊃2;, drilling depth 4D coolant pressure when the minimum 5KG / cm⊃2; more processing aperture tolerances, typically drilling depth for 2D / 3D when 0 / + 0.25; 4D when 0 / 0.40, but with different random bed and processing conditions will change avoid exceeding 6 ° slope, the concave surface uneven start drilling, it is easy to drill as the drill bit off-center or chipping, so if you have to do is feed the drilling must be reduced to the recommended value third. If you already have pre-drilled holes on the parts, the aperture of the hole shall not exceed the finished size of a quarter, otherwise it will lead partial drill. When there are intersecting hole drilling parts added together with the multi-sheet feed rate must be reduced to about one-third of the recommended values Lathe applicable Notes (the drill does not rotate) Ensure that the tool axis and spindle concentricity of less than 0.03mm, if necessary, make the appropriate correction needed the surface of the drill bit should be installed around the direction of movement of the blade parallel to the X axis of the machine, and on the outer periphery of the blade installation tool turret ensure that these conditions are met, the mobile tool axis direction along the X-axis machine tools, available in different hole diameter If the machining tolerances do not meet the requirements, please check the above items one by one and adjust the cutting parameters, improved cooling conditions Please note that if your CNC lathes have had the experience of the collision, it is difficult to ensure that the tool spindle axis concentric with the requirements of Warning: When drilling through the workpiece, the bottom piece of a high-speed flying disc-shaped waste, must take appropriate precautions to ensure the safety of Fast drilling and processing parameters are calculated as follows: Cutting speed (Vc): Example: Spindle speed for 1600rev / min, drill diameter Φ20mm, its cutting speed is: Vc = (20 × 3.14 * 1600) ÷ 1000 = 100 (m / min) Feed rate (VF): Example: Spindle speed for 1500rev / min, the feed per revolution of 0.1mm / rev, its feed rate is: VF = 0.1 × 1500 = 150 (mm / min) Hole machining time (Tc): Example: Drill a diameter Φ20mm, 40mm deep hole, the cutting speed is 100m / min, the feed per revolution of 0.1mm / rev, seeking drilling time: Vc = (100 × 1000) ÷ (20 * 3.14) = 1600 (rev / min) Tc = (40 × 1) ÷ (1600 × 0.1) = 0.25 (min) Metal removal rate (Q): Example: a diameter of drill Φ20mm feed speed machining of 160mm / rev, its metal removal rate:

Q = (160 × 3.14 × 202) ÷ (20 × 3.14) = 50.24 (cm3 / min)

'

Смотрите так же другие товары: