Новое поступление

4 шт./лот EJ179V QFN32 100% Новинка origina | Электроника

13S 48V 15A литий-ионная Защитная плата Lipolymer Battery BMS PCB Board с радиатором для E-Bike EScooter |

Хит продаж-5 шт. 1А 5В микро-usb TP4056 литиевая батарея зарядное устройство плата

Термоусадочная трубка 30 мм-250 мм прозрачная 18650 литиевая батарея пленка для ПВХ

MCZ3001DB MCZ3001D MCZ3001 IC | Электроника

2 МГц-700 МГц 3 Вт HF VHF UHF FM-передатчик широкополосный Радиочастотный усилитель

ADL5602 50 МГц до 4 0 ГГц широкополосный 20 дБ усиление RF линейный усилитель для Ветчины

Shop5384048 Store

Магазина Shop5384048 Store работает с 23.09.2019. его рейтинг составлет 98.08 баллов из 100. В избранное добавили 4519 покупателя. Средний рейтинг торваров продавца 4.9 в продаже представленно 34 наименований товаров, успешно доставлено 1117 заказов. 416 покупателей оставили отзывы о продавце.

Характеристики

3S 12V Lithium battery 3.7V power protection board temperature equalization function overcurrent BMS PCB | Электроника

История изменения цены

*Текущая стоимость 1 616,05 - 2 030,87 уже могла изменится. Что бы узнать актуальную цену и проверить наличие товара, нажмите "Добавить в корзину"

| Месяц | Минимальная цена | Макс. стоимость | Цена |

|---|---|---|---|

| Sep-16-2025 | 1923.87 руб. | 2019.84 руб. | 1971 руб. |

| Aug-16-2025 | 1907.99 руб. | 2002.63 руб. | 1954.5 руб. |

| Jul-16-2025 | 1600.39 руб. | 1680.71 руб. | 1640 руб. |

| Jun-16-2025 | 1875.41 руб. | 1969.99 руб. | 1922 руб. |

| May-16-2025 | 1632.50 руб. | 1714.41 руб. | 1673 руб. |

| Apr-16-2025 | 1842.37 руб. | 1934.3 руб. | 1888 руб. |

| Mar-16-2025 | 1826.71 руб. | 1917.17 руб. | 1871.5 руб. |

| Feb-16-2025 | 1810.25 руб. | 1901.2 руб. | 1855.5 руб. |

| Jan-16-2025 | 1794.19 руб. | 1884.61 руб. | 1839 руб. |

Описание товара

无标题文档

RECOMMEN | ||

|

|

|

Li-ion 3.6V / 3.7V 13S 48V BMS | Li-ion 3.6V / 3.7V 10S 36V BMS | Li-ion 3.6V / 3.7V 7S 24V BMS |

|

|

|

Li-ion 3.6V / 3.7V 16S 60V BMS | Li-ion 3.6V / 3.7V 14S 48V BMS | Li-ion 3.6V / 3.7V 20S 72V BMS |

Any questions please contact us!We will respond within 1 business day or less.

Bms is for battery use, different strings are not compatible.

E.g: 13S BMS, can not be used for 10S battery, can only be used on 13S battery.

product description

Range: nominal voltage is 3.6V, 3.7V lithium battery (including 18650, 26650, polymer battery).

Function: Overcharge protection function, over discharge protection function, over current protection function, short circuit protection function, battery balance management function, temperature protection function.

Products: 7S or more adopts Zhongying integrated scheme circuit, and 7S or less adopts single-section cascade scheme circuit.

无标题文档body table tbody tr td {

font-family: 思源黑体 CN Regular;

}

body table tbody tr td {

font-family: 思源黑体 CN Regular;

color: #000000;

}

|

|

|

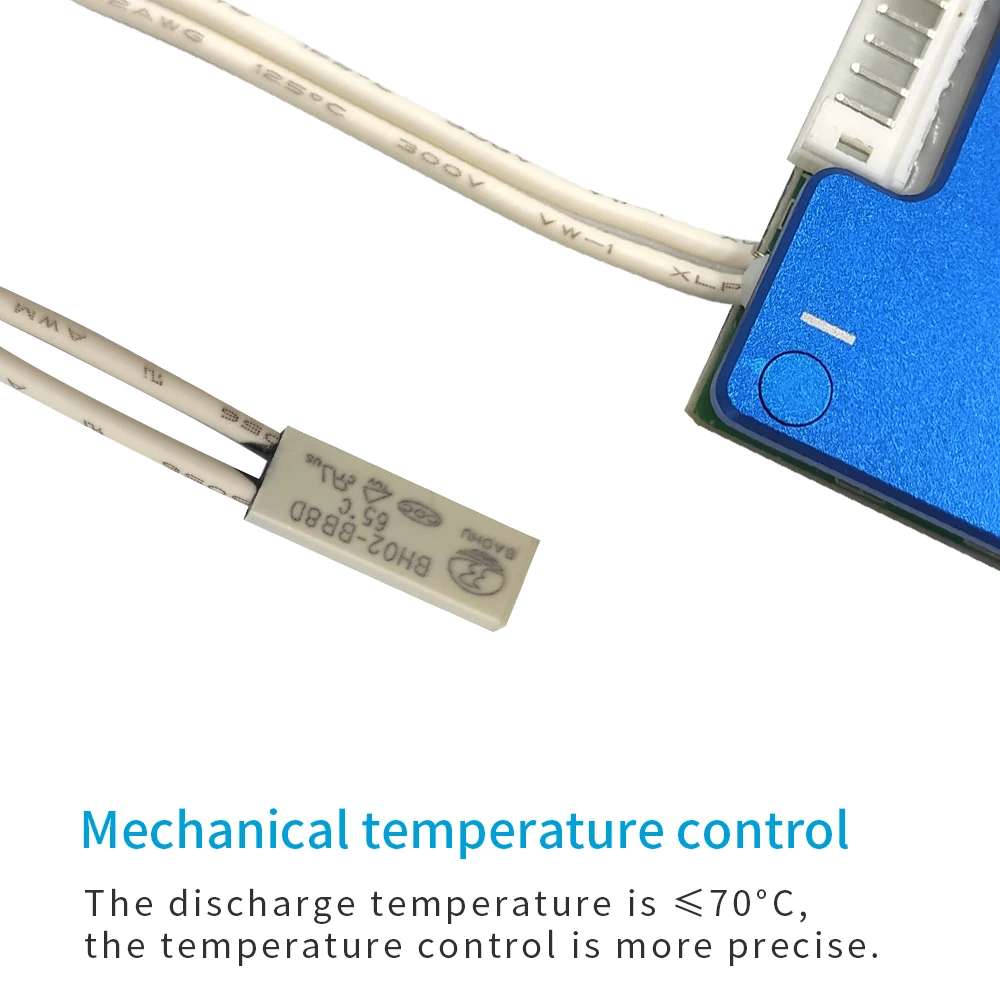

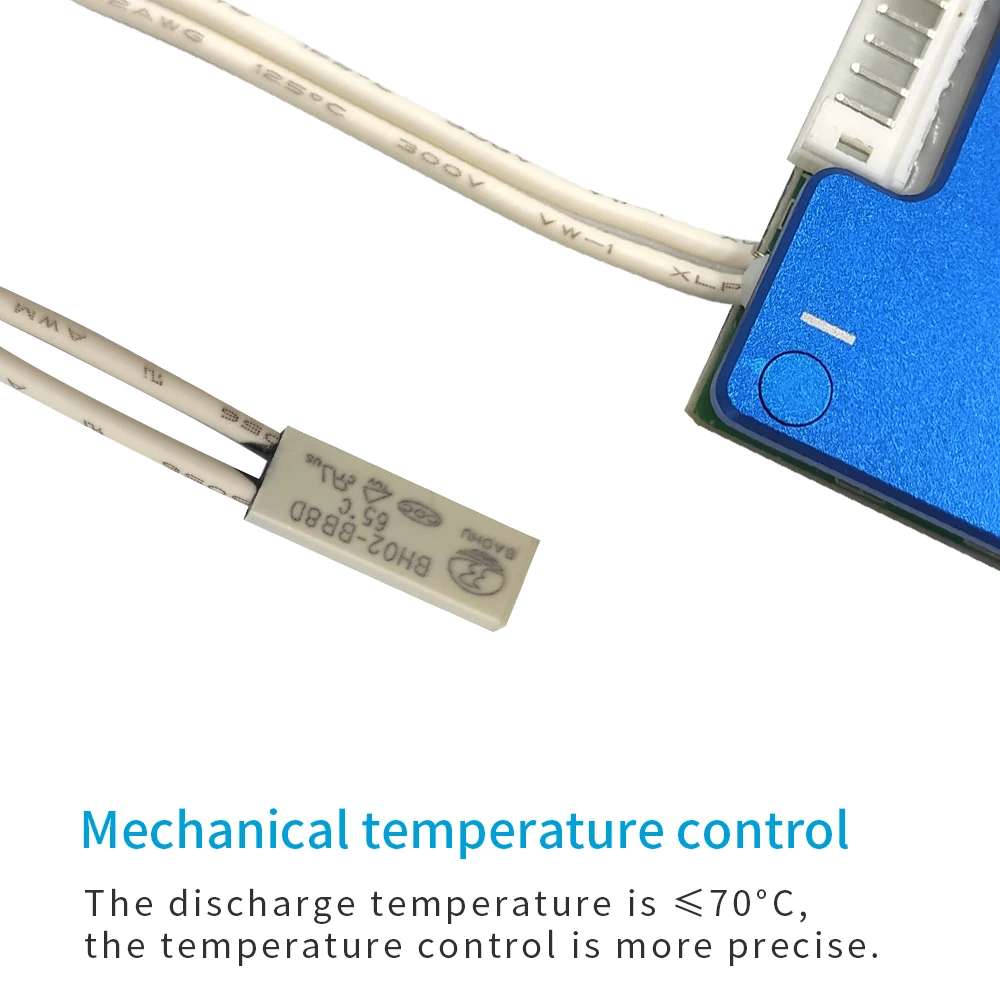

Temperature protection | Zhongying Integrated Circuit Solution | Three proof paint |

The 3-7S is equipped with a mechanical temperature sensor, which can realize functions such as overcharge and discharge temperature protection, effectively improving the safety of battery use, and solving potential safety hazards caused by thermal runaway of batteries. | The protection board responds accurately and sensitively, which has more advantages than traditional solutions, saves circuit space, and the parameters can be adjusted according to customer's customization to achieve the disconnection protection function. | All circuits are coated with three anti-paints, which can effectively prevent electrostatic damage, prevent short circuits caused by humid environments, prevent air oxidation, and extend service life. |

|

|

|

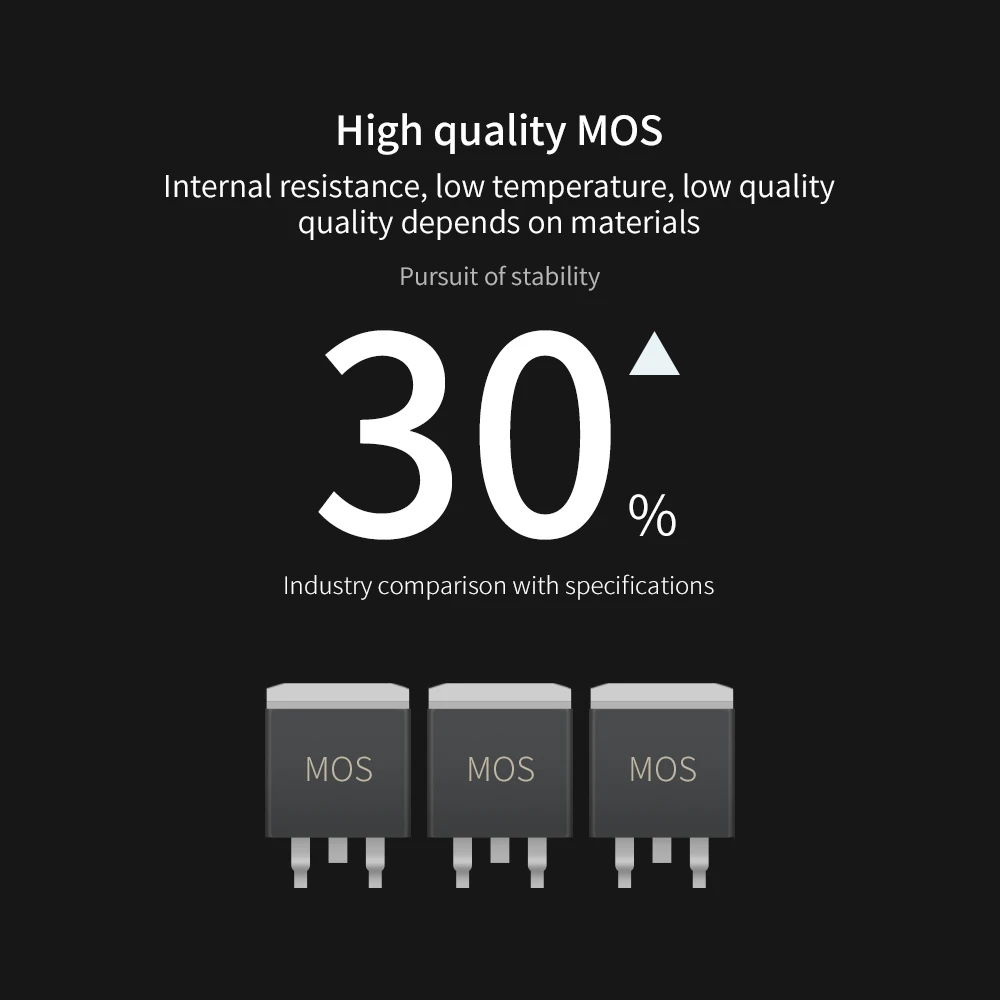

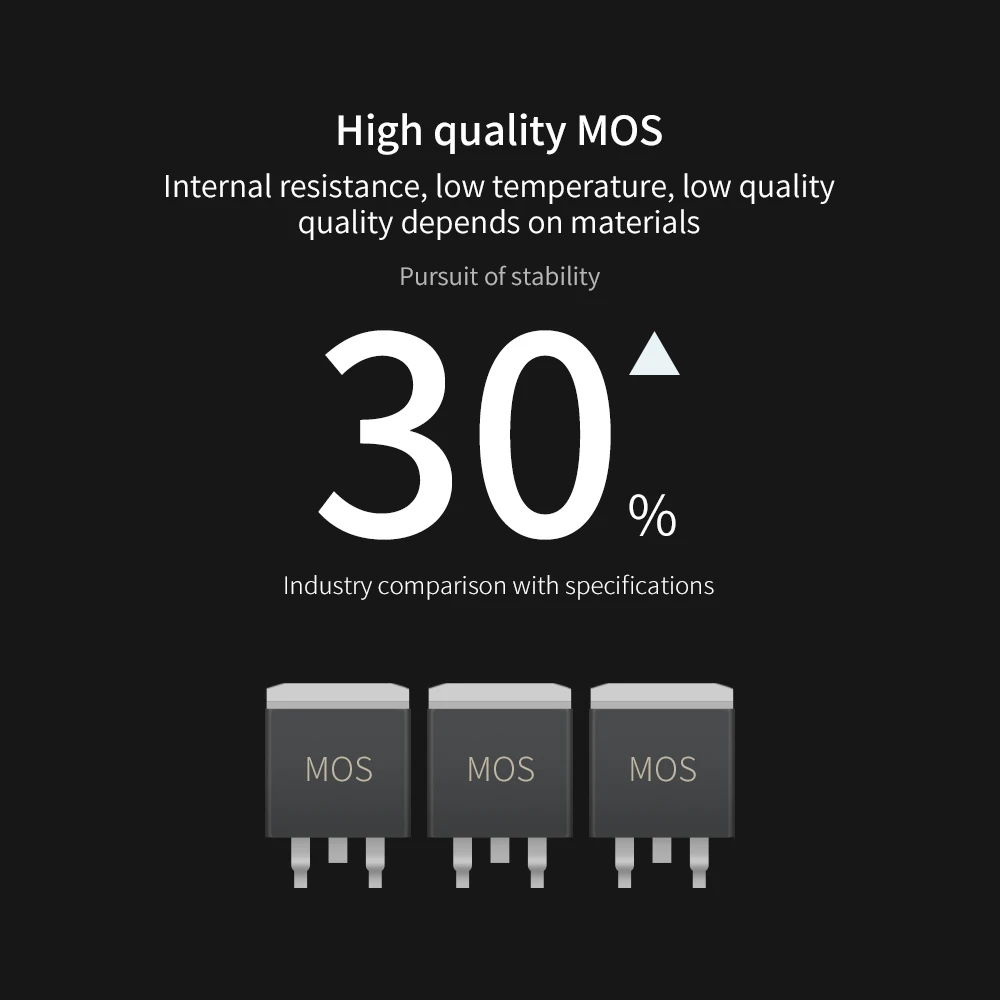

New Class A MOS | Strong heat dissipation | Send matching cable |

The use of AVIC MOS can ensure product quality, low internal resistance during discharge, and low temperature rise during long-term discharge, without affecting the output of the battery, making the control safer. | The heat sink is anodized, and the heat-conducting silica gel is cushioned to improve the heat dissipation efficiency. The structure is transparent and has a better temperature environment than the sealed type. Long-term discharge does not affect performance. | White and red colors are sent randomly with the same effect. |

Charging

Charge current:Same as continuous current

Charging voltage:12.75V

Over charge protection

Overcharge detection voltage:4.25V±0.05V

Overcharge release voltage:4.15V±0.05V

Overcharge protection delay:600uS

Over discharge protection

Over discharge protection voltage: 2.7V ± 0.1V

Over discharge release voltage:3V±0.05V

Over discharge detect delay:600uS

Balance

Balance detection voltage:4.18V

Balanced release voltage:4.18V

Balance current:35mA±5mA

Overcurrent protection

Instantaneous current: continuous current * 2.5

Overcurrent detection delay:600uS

Overcurrent detection voltage:100mV

Overcurrent protection release condition:Disconnect load

Short circuit protection

Short circuit protection condition:External load short circuit

Short circuit detection delay:600uS

Short circuit protection release condition:Disconnect load

Temp Protection

Charging temperature: ≤65 ℃

Discharge temperature: ≤65℃

Remove temperature control protection: within working temperature

Inner resistance

Main circuit on-resistance:≤10mΩ

Self electricity consume

Working current:≤100uA

Sleep current (when the battery is over-discharged):≤20uA

Working Temp

temperature range:-20℃/+80℃

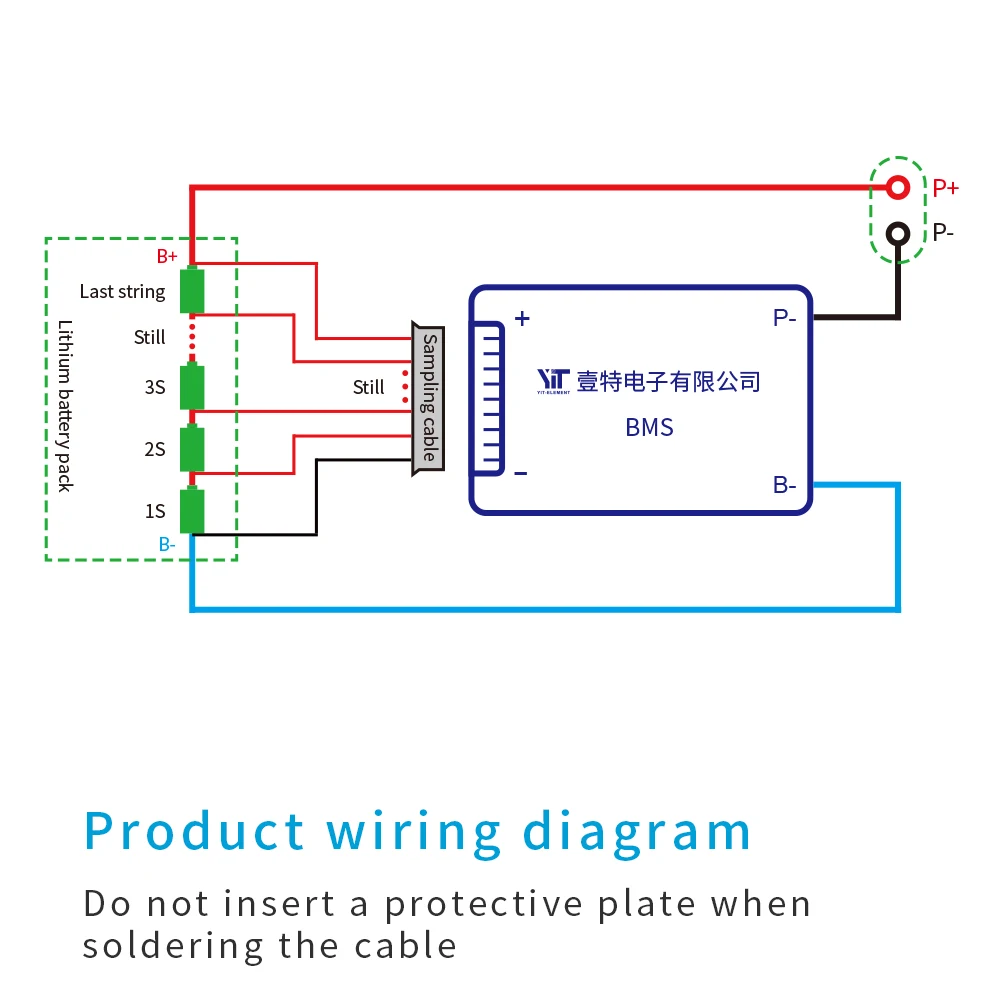

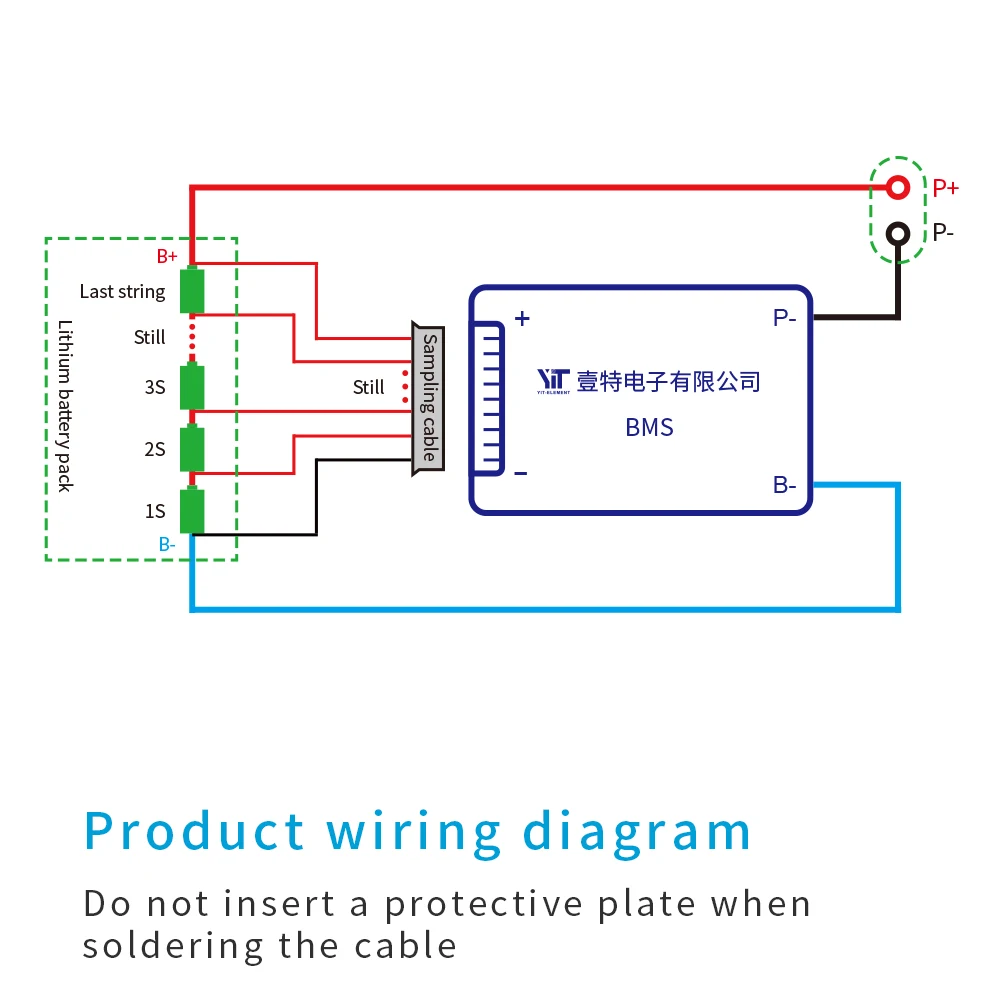

Use the sequence of operations:

1. The cable starts from the black thin wire connecting B-, the second wire (the thin red wire) is connected to the positive pole of the first battery, and the positive pole of each battery is connected in turn until the last red wire is connected to B+;

2. After connecting the cable, do not insert the plug directly into the BMS. Measure the voltage between each two adjacent metal terminals on the back of the plug. If the voltage of the terpolymer battery should be between 2.8V and 4.2V, the iron-lithium battery should be between 2.5V and 3.65V.

3. After correct wiring sequence and voltage confirmation, insert the BMS socket.

4. The protective board B line (blue thick line) is connected to the negative pole of the battery pack.

5. After the wiring is completed, measure whether the total voltage of the battery pack and the total voltage passing through the BMS are equal. If they are different, check again according to the above wiring sequence.

Tips

The battery pack protection board, which is a semi-finished product of electronic products, is a wearing part in case of wrong use.

If you don't understand how to use it, please read the manual carefully or ask the customer service. Any wrong use will burn out the front-end sampling resistor. We will not accept such disputes of customer damage. Please do not buy if you mind.

Tips

The electronic switch formed by the protection board through the MOS, because of the voltage induction and the low internal resistance of the MOS, some virtual voltage appears when it is turned off. This voltage cannot be used, and there will be no spark even if there is a short circuit. If you mind, don't buy it.

Precautions

1. Lithium battery protection boards of different voltage platforms cannot be mixed. For example, iron-lithium batteries cannot use the protection board of ternary batteries;

2. The design parameters and conditions of use must be followed during use;

3. The charging and discharging currents must not exceed the rated value;

4. Please use the protective plate within the specified working temperature and ensure a good heat dissipation environment around the protective plate;

5. Do not disassemble or change the components of the protection board by yourself;

6. Avoid contact between the heat sink and the battery core and nickel strip during assembly.

Смотрите так же другие товары: